Here are the reasons why our motorcycle accessories are of quality!

With the advent of the internet today it is possible to find products with more varied prices, but why do I find such different prices for apparently similar products?

Well, if you asked yourself this question then look hard and you are not only attracted by deceptive prices and scandalous products.

Today's market is invaded by really ugly products, but the inexperienced user feeds them by buying them, not understanding the reasons why they should not buy them. Factors affecting the price of products developed by craft companies like us are:

quality of materials

work quality

quality of finishes

Intellectual property

product customization

Quality of materials

Our products are made only with the best materials, all the workmanships are carried out with extreme accuracy.

We only use aluminum in ergal 7075 or "anticorodal" 6060 alloy, as these aluminum alloys guarantee a mechanical resistance and characteristics that adapt to the stresses to which they are subjected, this is a guarantee sufficient to prevent breakage, maintaining a level of safety superior and, important in this case, ensuring a very nice and particularly beautiful final appearance.

Some components to ensure superior quality are tested in the laboratory or in circuit by our pilots, with whom we collaborate, to guarantee the standards that all SRT products must have.

Monteresti on your bike a handlebar made in China at low cost with some kind of material?

Or would you like to use low-cost brake levers that might break up in an emergency stop?

Do you think that the Chinese carter pads or protectors are tested on the track by pilots? We doubt it ....

SRT recommends changing the motorcycle only with quality components!

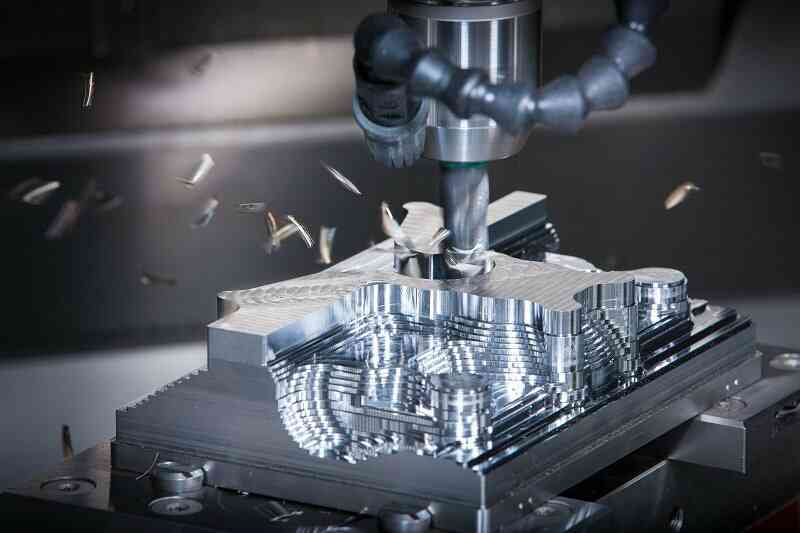

Machining quality

We carry out the main workings with latest generation numerical control machines, this allows a faster production and a better quality of processing, moreover the machineries used allow very particular workings, among which the 3D is so fashionable today.

The numerical control machines guarantee very high quality standards, allowing to reproduce the products in series in perfect way with great precision.

Currently we have machines to perform the following processes:

- 3D microfusion printer

- CNC laser cutting

- 5-axis CNC milling with 3D technology

- CNC turning with integrated cutter

- CNC bending machine

This fleet allows us to perform every kind of element for the bikes currently produced.

But how does the quality of the work on the cost of the product affect?

Ever heard the term "time is money"? Here is the summary of everything, the faster the cars travel, the more pieces come out and the less they cost. However, the downside is less precision or accuracy of details.

If this factor we imagine on a counterweight the problem is only aesthetic, but imagine we have an imprecision on a brake lever that once mounted keeps the pumping slightly under pressure and the bike just braked! This can cause overheating of the braking system which compromises safety !!!

Would you ever risk your life for a few tens of euros?

Finishing quality

The finishes affect the production in a very heavy manner if carried out with care and attention.

A product like the "luxury" accessory for the bike must be nice to see! It is not enough to draw it with appeal if you then leave it rough.

We carry out the following finishing operations:

- anodization

- chrome plating

- painting

- brushing

- tumbling

- sandblasting

- laser engraving

Each of our products is subjected to one or more of these treatments that are performed in several stages, and this entails additional costs if high quality is required.

These treatments serve to guarantee, based on the material, a final effect that is not only satisfying from an aesthetic point of view but protective for years from the atmospheric agents to which the components will be subjected in time.

For example, our handlebars are made from aluminum bars that are "beaten" continuously in the transport by presenting small marks.

Before being bent the bars are subjected to the "brushing" that eliminates the signs of transport and gives a finished effect of the handlebars, this treatment has a cost but is performed to improve the final appearance of the product. After which the bending and anodizing and finally the lasering are carried out. So even a simple product like a handlebar actually involves some work to improve the final result.

But where you really miss the quality when you save is on the anodizing of aluminum.

Have you ever bought products, such as reds, which then actually came in pink or that turned black after 3 months to brown?

Well this happens because you save on anodizing! So you have products with bright and ugly colors that after a few months totally lose color.

Intellectual property

Design is a word that in modern jargon is used continuously, but that often is not given the value it should have.

Because? Because it is the aesthetic factor that affects the value of the product. Would you ever buy an ugly product? Obviously not.

But you would never buy a useless product.

As a result, our job is to design, study and develop a product that is first and foremost useful. Then it will then be necessary to create a design that pleases and is balanced but at the same time compatible with the SRT style.

This involves a further phase of study that takes time .... you remember the saying above "time is money", so this time comes at a cost.

Making a product without design and style does not involve efforts and costs, making beautiful and rewarding products, on the other hand, gives a superior value to the product that has led to a study to arrive at the final result.

We define this work as the intellectual property of the product, of the idea and of the design.

Product customization

Over the years our company has specialized in the production in large series of accessories in aluminum and titanium. Initially, as well as for our company, we worked with motorcycle accessories and original equipment. Even today we continue the partnership with some of them, but with the advent of China many of our partners have turned to this type of market for purely economic issues.

From 2015 to overcome this situation we have joined a development department for the production of particulars in micro batches with very low quantities and even prototyping. We have opened collaboration channels with special "preparers" and with designers who create the motorcycles of tomorrow with their unique inspiration.

So we are structured to provide a service to all those who make limited series of motorcycles, or prepare special tailor-made.

Today we work with both professionals and individuals who request products that are designed specifically for the customer.

For more information visit our new SPECIAL section